Are PACCAR engines built by Cummins?

While PACCAR and Cummins are both well-respected brands in the heavy-duty trucking industry, their engines have some differences. PACCAR engines are designed and manufactured in-house, while Cummins engines are built by a separate company. As a result, PACCAR engines are typically only used in PACCAR trucks, while Cummins are used in a variety of different truck brands.

In terms of performance, both engines have their strengths and weaknesses. PACCAR engines are known for their durability and fuel efficiency, while Cummins engines are known for their power and reliability. Ultimately, the decision between these engines will depend on the specific needs and preferences of the truck owner.

Here is a list of some of the engines that PACCAR offers:

MX-11: A 11-liter inline six-cylinder diesel engine used in medium-duty trucks and buses.

MX-13:A 13-liter inline six-cylinder diesel engine used in heavy-duty trucks.

MX-15:A 15-liter inline six-cylinder diesel engine used in heavy-duty trucks.

PX-7:A 7-liter inline six-cylinder diesel engine used in medium-duty trucks.

PX-9:A 9-liter inline six-cylinder diesel engine used in medium-duty trucks.

PX-11:A 11-liter inline six-cylinder diesel engine used in medium-duty trucks.

PACCAR also offers a range of hybrid and electric powertrain systems for its trucks and buses. These include the Kenworth T680E electric truck and the Peterbilt 579EV electric truck.

Cummins motors are built to provide reliable and efficient power for a wide range of applications.

Whether it's powering a heavy-duty truck across long distances or providing electricity to a remote village, these engines are designed to meet the needs of a diverse set of customers.

Here is a list of some of the engines that Cummins offers:

B Series:A range of inline four- to six-cylinder diesel engines used in light-duty trucks, buses, and other commercial vehicles.

ISB:A 6.7-liter inline six-cylinder diesel engine used in medium-duty trucks and buses.

ISC:An 8.3-liter inline six-cylinder diesel engine used in medium-duty trucks and buses.

ISL:A 9-liter inline six-cylinder diesel engine used in heavy-duty trucks and buses.

ISM:A 10.8-liter inline six-cylinder diesel engine used in heavy-duty trucks and buses.

ISX:A 15-liter inline six-cylinder diesel engine used in heavy-duty trucks and buses.

L Series:A range of inline four- to six-cylinder diesel engines used in agricultural, construction, and other off-road applications.

N Series:A range of inline four- to six-cylinder diesel engines used in light-duty trucks, buses, and other commercial vehicles.

Cummins also offers a range of natural gas engines, including the ISX12 G, a 12-liter inline six-cylinder natural gas engine used in heavy-duty trucks, and the B6.7 G, a 6.7-liter inline six-cylinder natural gas engine used in medium-duty trucks and buses.

Is the PACCAR PX-6 a Cummins Engine?

According to several forums where this is discussed by truckers, we found that the consensus is that the PX-6 was manufactured by Cummins for PACCAR and is based on the Cummins ISB engine. That doesn’t mean the PACCAR PX-6 and Cummins ISB engines are identical though.

Here are some of the specifications for the PACCAR PX-6 engine:

Displacement:7 liters (410 cubic inches)

Configuration:Inline 6-cylinder

Bore x stroke:21 x 4.88 inches

Compression ratio:5:1

Aspiration:Turbocharged and air-to-air intercooled

Fuel system:Electronic high-pressure common rail

Maximum horsepower:200-325 horsepower

Maximum torque:520-860 lb-ft

Emissions compliance:Meets EPA 2010 and Euro 6 emissions standards

Is the PACCAR PX-7 a Cummins Engine?

Once again as with the PX-6, it appears that Cummins manufactured these engines for PACCAR.

A June 26, 2006, from PACCAR.com made these key statements:

PACCAR and Cummins have announced an agreement for the installation of Cummins 6- and 8-liter engines in Peterbilt and Kenworth medium-duty commercial vehicles in North America.

The engines will be branded as PACCAR engines and will be exclusive to these vehicles.

This agreement expands upon the existing engine collaboration between DAF and Cummins in Europe, where the Cummins 4- and 6-liter engines are exclusive to the DAF LF product.

The North American agreement allows PACCAR to compete with other manufacturers that have their own proprietary medium-duty engines.

This agreement will also significantly reduce the cost of homologating multiple engines for compliance with 2007 EPA regulations for PACCAR's chassis.

Peterbilt and Kenworth will continue to offer their customers a choice of engines in their Class 8 vehicles.

As you can see, Cummins manufactured these engines specifically for PACCAR, and “the engines will be branded as PACCAR and will be made exclusive to these (PACCAR) vehicles”.

Here are some of the specifications for the PACCAR PX-7 engine:

Displacement:2 liters (441 cubic inches)

Configuration:Inline 6-cylinder

Bore x stroke:21 x 4.88 inches

Compression ratio:5:1

Aspiration:Turbocharged and air-to-air intercooled

Fuel system:Electronic high-pressure common rail

Maximum horsepower:200-350 horsepower

Maximum torque:520-860 lb-ft

Emissions compliance:Meets EPA 2010 and Euro 6 emissions standards

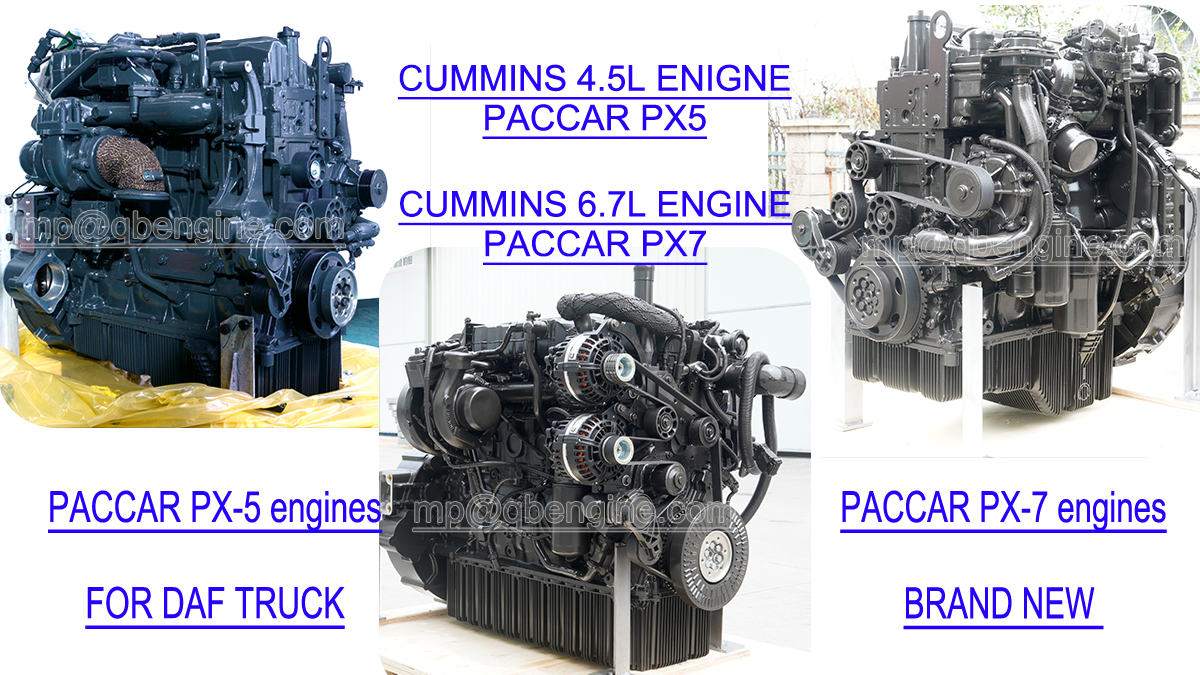

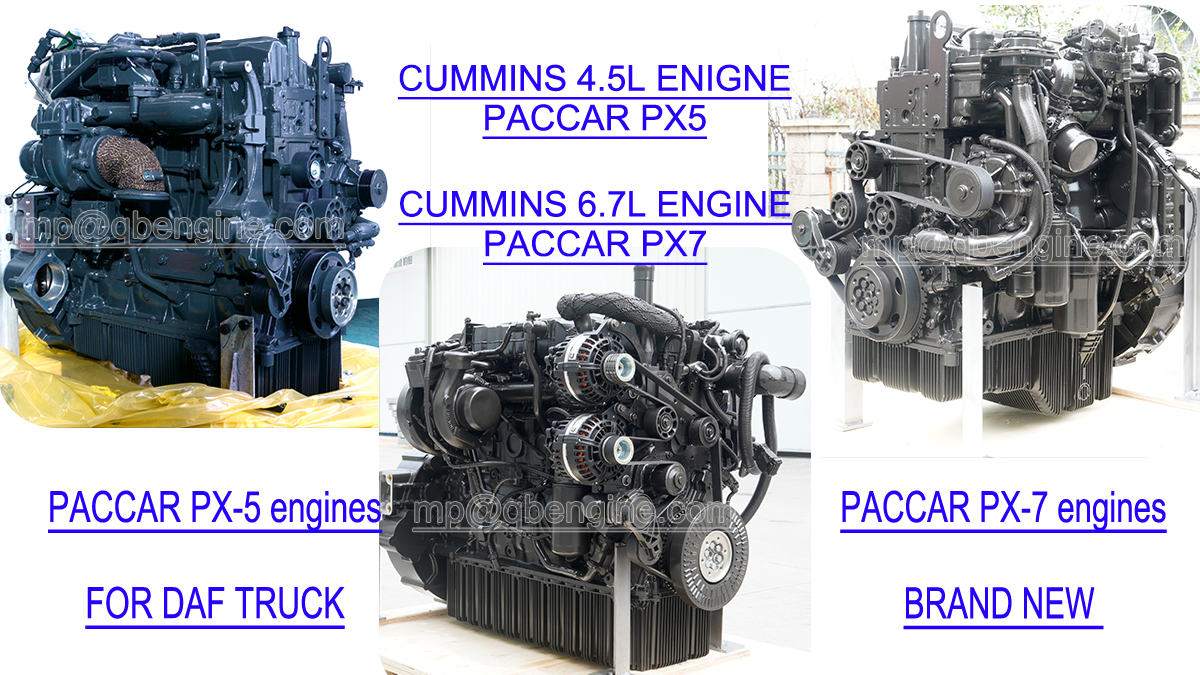

PACCAR PX-5 engines

Paccar’s PX-5 engine manufactured at Cummins Darlington is equally at home in the countryside as the city, seen here powering a DAF LF mini-tanker able to navigate the narrow, steep lanes of the South Downs in Hampshire keeping rural homes supplied with domestic fuel oil.

The 4.5 litre Euro 6 PACCAR PX-5 engine uses common rail technology, a turbo with variable geometry and advanced controls for maximum efficiency. In order to comply with the strict Euro 6 emissions requirements, it features exhaust gas recirculation, together with SCR technology and an active soot filter.

General information

Four-cylinder in-line turbocharged diesel engine with intercooling. Ultra clean combustion with Exhaust Gas Recirculation (EGR), Diesel Particular Filter (DPF) and Selective Catalytic Reduction (SCR) aftertreatment for Euro 6 emission levels.

Main construction

Cylinder block - cast iron stiffened ladder frame, contoured and deep skirted with cylinder bores direct in the block

Cylinder head - one-piece cast iron cross-flow type cylinder head composite valve cover

Valves - four valves per cylinder

Pistons - aluminium alloy pistons, Ni-resist with symmetrical re-entrant combustion chamber; gallery cooled

Piston rings - 2 compression rings; 1 scraper ring

Crankshaft - forged alloy steel with balance weights; supported in 5 bearings

Cam shaft - steel forged and induction hardened supported in 4 bearings; driven from the timing gears (single plain train at the rear of the engine)

Oil sump - 17 litres composite oil sump, closed crankcase ventilation with impactor

Fuel injection and induction

Fuel injection - Common Rail (CR) injection system

Injectors - electronically controlled

Injection timing - variable start and duration, electronically controlled

Injection pressure - max. 1800 bar

Fuel injection - start and duration, as well as the injection pressure, are controlled by the engine mounted electronic control module

Induction - turbocharged with charge cooling (intercooling)

Turbocharger - variable geometry turbocharger (VGT) with electrical actuator

Emission - control exhaust gas recirculation (EGR

Lubrication

Oil filter - full-flow oil filter with replaceable element

Oil cooler - coolant-to-oil plate type heat exchanger

Oil pump - concentric oil pump, driven by crankshaft

Cooling system

Pump - belt driven centrifugal pump

Thermostat - single wax type in cylinder head

Fan drive - crankshaft driven with temperature controlled viscous coupling

Expansion - tank translucent tank (for visual level check) behind the front grille panel

Auxiliaries and exhaust brake

Compressor - driven from rear timing gears

Alternator - poly-V-belt driven at engine front

Steering pump - driven from timing gears (via compressor)

Exhaust brake - VGT turbo with electrical control

Distribution applications up to 16 tonnes

The 4 cylinder PX-5 engines are suitable for trucks up to 16 tonnes. They are available with outputs up to 210 hp with a high maximum torque of 850 Nm. The engines have composite oil sumps to save weight and reduce noise. The engine mounts isolate engine vibrations from chassis and cab. Efficient fans provide high cooling air flow against a low power demand. The engines feature a fast transient response and general driveability. The availability of more torque at a low engine speed results in better drive-off characteristics.

Performance

All PACCAR PX-5 engines deliver excellent torque at low engine speeds resulting in easy and comfortable driving, even in dense traffic without frequent gear changes. The characteristics make the PX-5 engines pre-eminently suitable for tough inner-city distribution jobs. The standard exhaust brake delivers up to 95 kW braking power.

Fuel efficiency

A well-controlled combustion process together with additional technology to achieve the ultra-low Euro 6 emission values. The highly efficient combustion results in an excellent fuel economy as another leading edge of the PACCAR PX-5 engines.

Environment

PACCAR PX-5 engines use the proven PACCAR technology for exhaust gas aftertreatment, consisting of a Diesel Particulate Filter (DPF) and a Selective Catalytic Reducer (SCR) with airless AdBlue injection. The neatly packed aftertreatment unit is placed at the right-hand side of the chassis. A vertical installation behind the cab is available for specific applications.

PACCAR PX-7 ENGINE

The PX-7 makes a new name for dependable precision. With smooth operation and an excellent power-to-weight ratio, this engine sets new standards for medium-duty power.

The 6.7-liter PACCAR PX-7 engine delivers superior performance, minimizes operational costs and maximizes uptime for medium-duty customers. Reduced maintenance, long service intervals and excellent fuel e�ciency add up to a superior lifetime value.

The PACCAR PX-7 is available in horsepower ratings from 200 to 360 HP and offers up to 800 LB.-FT. of torque.

TRUSTED DEPENDABILITY - ELECTRONIC CONTROL MODULE

As the brain of the PX-7, the ECM accurately controls all engine functions of optimum performance and fuel economy.

TRUSTED DEPENDABILITY - LIGHTWEIGHT PACKAGE

The PX-7 unites a lightweight design with high sctructural integrity, providing a durable solution for miles of reliable service.

TRUSTED DEPENDABILITY - VARIABLE GEOMETRY TURBOCHARGER

The infinitely adjustable VGT provides you the exact boost needed for a fast, superior response.

PEAK HORSEPOWER | PEAK TORQUE (LB.-FT. @ RPM) |

| CONFIGURATION | Inline 6-cylinder |

200 | 600@1300 | BOREXSTROKE(MM) | 107x124 |

220 | 600@1300 | DISPLACEMENT | 6.7 L. |

240 | 600@1300 | DRY WEIGHT | 1,150 LBS |

250 | 660@1400 | OIL SYSTEM CAPACITY | 19.5 U.S. QTS |

260 | 660@1400 | HORSEPOWER | 200-360 HP |

280 | 660@1400 | PEAK TORQUE | 520-800 LB.-FT. |

300 | 660@1600 | GOVERNED SPEED | 2,600 RPM |

325 | 750@1600 | CLUTCH ENGAGEMENT TORQUE | 400 LB.-FT. @ 700 RPM |

340 | 700@1600 | BASE WARRANTY | 3 YRS./UNLIMITED MILES |

360 | 800@1800 | CERTIFICATION | EPA 2024 |